For the very first time, André Eriksen, creator and CEO of Asetek, agrees to be interviewed by a French-speaking media outlet. Naturally, we’re very proud to be the lucky ones. All the more so since, in this interview, André is going to share with us a few nuggets and exclusives that he’s been keeping quiet about until now.

We’ll let you discover them in the video we shot on the spot, as well as in the full transcript below 😉

Hello André Eriksen, can you introduce yourself and tell us where we are?

Yes, my name is André, and I’m the founder of Asetek. We’ve been around for over 20 years now. Right now, we’re in our Danish headquarters, in Aalborg in northern Denmark. And to be more precise, we’re in our Race-shop where you can see our racing cars.

Why did you choose to diversify into simracing two years ago?

Well, that’s a good question. As a company, we don’t have a racing heritage. We make liquid coolers for gaming computers. But we’ve spent the last 5 or 6 years figuring out what’s next for us. And there were two obvious avenues open to us.

The first was to make more equipment for gamers. Or to find other applications for our cooling systems. So we delved into the subject of electric cars, industrial and military lasers, Hifi equipment, LCD projectors, DLP projectors, all sorts of things where liquid cooling could prove useful.

And what we realized was that we weren’t experts in implementing solutions in these sectors

in these sectors, so it’s hard to get into. Because liquid cooling isn’t like a screw. It’s something made to measure.

And then we looked at the other side, at other possibilities. So, do we go for gaming chairs, keyboards, mice, headsets, things like that? But… In fact, we like to shake things up, we like to innovate, and how can we innovate in these sectors?

That’s one reason. The second is that we’d find ourselves in direct competition with our customers

and I don’t think it’s a good idea to compete with our customers. So it didn’t really make sense either! And then..

I don’t know if you’ve seen our E-Sports Academy upstairs? It’s a corporate social responsibility project. Children and young people from the town and surrounding area can come and play for free… They mainly play Counter Strike.

We have the best equipment money can buy, made by our customers, with our cooling systems of course. And young people can use them. And when we set up this E-Sports Academy

I thought, “What if we put in driving simulators too?”

Because maybe not all young people want to play FPS. Maybe there are some who’d rather drive instead. So we put together 5 racing simulators, and it turned out to be the main reason we chose to do this. Because at no point in time did we manage to run all 5 simulators at the same time!

Either the pedals had a problem, or it was the paddles, or there were problems with the software, the driver, the firmware… And because I have a background in racing, an experience of many years, I’ve been building simulators myself for years.

So I thought about all that and I said to myself, “I think we can do better than this, we can do this better.” Better quality, better integration, simplicity of use… Because simracing today is a market that speaks well to enthusiasts who love tinkering, making holes, putting things together

and like to get their hands dirty with software. But there are also a lot of users who don’t want to do that.

I’d say that the user experience we’ve had with 5 so-called high-end products has really pushed us in that direction. And if you take the time to think about it, now you’ve been around the company, you’ve seen all the engineers we have…

There are a lot of them! And they represent every specialization. We have thermodynamics, of course, for our liquid cooling systems, but we also have specialists in mechanics, software, hadware, low-level software… We have it all.

And if you take a closer look, a car simulator is mechatronics. What are mechatronics? Hardware, software and mechanics. And the fact that we already have these skills in-house is what made us decide to enter the simracing market.

It’s a long answer, but there were strategic reasons behind the choice.

Could you tell us a little about your racing experience?

Yes. When I was a kid, I used to race motocross, and did so for many years

then I had other interests, founded Asetek and didn’t race for years.

Then, in 2007, I moved to northern California and got back into it. The climate was wonderful, and I lived right between the Sonoma trail and Laguna Seca. Laguna Seca was 25 minutes from my house. We had a lot of fun, and there were lots of nice tracks around, so I took up Go-Karting. Basic stuff, no gearbox, nothing complicated.

I learned to drive it and became California champion in… I can’t remember… 2010 or something like that. Then I switched to Karts with gearboxes. I took part in the US Nationals

and when that was over I moved on to Formula.

And, of course, I wasn’t going to make a career out of it, I was too old, I’ve probably got much more to gain from Asetek than from racing. So I switched to Formula, but rather than starting with Formula 4, for example, I started with the Pro Formula Master, which is closer, I’d say, to a Formula 3. Quite powerful and light.

So I did that for 3 years and my best result was finishing 2nd in the championship. That was pretty good! We traveled to a lot of American tracks. And then for TrackDays and isolated races I drove all sorts of cars.

But what’s interesting is that I have two children. Sophia and Valdemar. And they had also taken up Go-Karting at the age of 7. So when we lived in California, there were 3 of us driving. Racing was our life

You know, our friends and families were in Denmark of course… In Europe, in a different time zone… We didn’t have much else to do than work or race.

So we spent weekends, weeks, whole vacations in our camper van with our family, going from tour to tour in the USA. Then we came back to Denmark and I stopped racing. Now I just drive Go-Karts on Danish tracks and a few European ones.

My daughter has stopped too. I’d say it’s lucky for financial reasons! But my son carried on. So we did Formula Ford, Formula 4, we had two F4s that were ours, we had an F4 team. And then he did the MRF Challenge twice in Asia, in F3s. And then he did the Spanish F4 championship. Then, again for financial reasons, we could no longer afford to enter Formula 3, so we switched to GT3.

He’s now in GT3 for 2 seasons. And next year we’ll probably move up to Le Mans Prototypes. So, I’d say I have a pretty broad experience with all types of racing vehicles. And I’ve been to a lot of Formula 1 races. Since we’re sponsoring Kevin Magnussen, I’ve got access there

And beyond that, I’m a big car enthusiast. I’ve got a few cars myself and friends who have quite a few supercars. So I’d say I have a pretty broad experience with all types of vehicles, racing or not. Without ever having been a professional driver, of course.

You were able to do all this while growing the company right up to its IPO?

Yes! You know, in Denmark right now there’s the subject of work-life balance, which is very hot. But I’ve always taken a very different approach.

I only have one life. I don’t have a work life and a home life. Because when I founded Asetek I had customers in the USA, customers in Australia, in Europe so I’m never really on a break. But you might say, “Okay, so you’re never really at work either”, but I am!

I can work just about anywhere. As well as cars, I race snowploughs and jet skis. I love anything with an engine! We’ve got a house in Norway, for example, and we go there and I have fun with my family for 2 or 3 days, then I work 2 or 3 days non-stop and… you know, I don’t say to myself “Okay, you’re on vacation for 4 weeks or 3 weeks, only to find that I’ve got 2,000 e-mails when I get back.

I prefer to keep up the pace all the time. That’s how I did it. Maybe it’s different, but that’s how I do it and it works well, and with my family it works well too, and thanks to the race we’ve spent a lot of great time together as a family. We’ve crossed the USA, we’ve run in Dubai, in Europe… We’ve traveled everywhere together as a family and it’s great.

You see, for example, in 2 days’ time, on Thursday, Valdemar and I are going to Barcelona. He’s got a GT World Challenge race and, of course, for the first two days I’ll be at the hotel doing my job. He’ll be testing, qualifying and so on. And I’ll be joining him at the track on Saturday and Sunday.

Getting back to Asetek SimSports, how do you position yourself in the competitive world of simracing?

I’d say the simulation market has changed quite a bit since we decided to get into it two years ago. You know, we’ve got a few entry-level brands that have come out with products that look very good from the outside. At very affordable prices.

I’d say the problems we had with some of the simulators we built (for the E-Sports Academy) have been solved. Some brands have the same strength as us, so yes, the competition has changed. But I would say that our mantra, what we believe in and what comes from our experience in liquid cooling is… so of course you’re never going to interview a CEO who’s going to tell you that his products are bad..

But when I say we do quality, what I mean is that we spend a lot of time… And you’ve seen our test room, we spend an enormous amount of resources testing our products before launching them on the market. That’s not to say we’re perfect and don’t make mistakes.

But we do take the whole aspect of user experience and material quality very seriously. And that comes from our cooling business. Because if we sell a $100 cooling system to Dell

they put it in a $5,000 computer and it leaks! Then Dell has a $5,000 problem and it becomes our problem.

So… selling to these companies, like in the automotive world, requires very, very high quality. That’s one of the reasons. The other reason is, and I think this shows on our products, we also showcase Danish industrial design know-how. We try to make products that are beautiful, with style, and I make it a point of honor not to copy others.

So, we’re not blind, a screw is a screw… But we tried to come up with something that nobody else had done before, and you’ve seen the machines we have on site. If we’d wanted to, we could have copied equipment already on the market and launched the products in a matter of weeks. In fact, that’s what some people do. I’m not judging whether it’s good or bad, it’s just not what we do.

And because we make products designed and thought out for mass production… For example, if you look at our pedal arms on the Invicta and the Forte, they’re the same!

If you want to machine a CNC aluminum arm like that, it costs $200. But since we mold them, it’s a fraction of the price. And you can put more money into the machines, because they require quite a bit of investment. But that’s why we can offer them at affordable prices. So we go through mass production, and I wouldn’t say we’re “cheap” but rather that we give more value.

If you look at the hydraulic cranksets on the market, for example, they’re 2 to 3 times more expensive than we are

often they’re car cranksets that have been adapted with other parts from the automotive industry. And the price is much higher, but I think that for the end result, our products are not expensive.

And then we really try to provide good customer service and support. We’re not going to push things to extremes because I lived in the USA for years and there it’s… You come from France. In Denmark, we like to say that French companies hate their customers. There’s some truth in that! And you could say that the USA is the opposite: the customer is always right. I don’t want either.

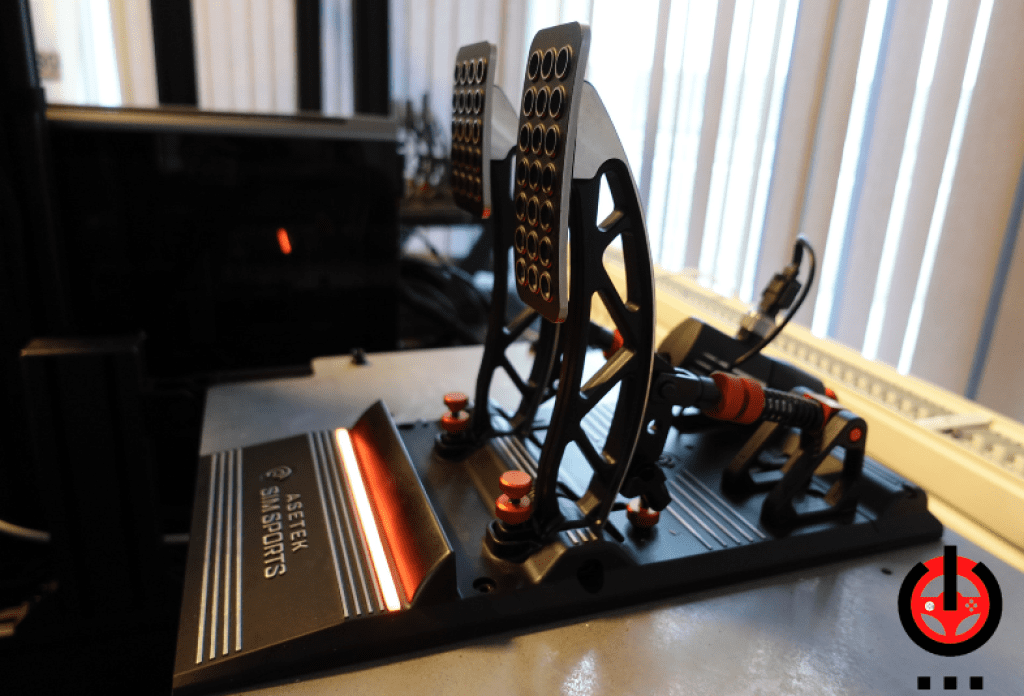

But we try to have good customer service. And I’d say that the sum of all that is what sets us apart. If you look at the Forte pedalboard, the Load Cell pedalboard. If you look closely, it’s an Invicta pedalboard

crankset, it’s just that it has a Load Cell instead of a hydraulic cylinder. And in terms of price, I find it very competitive

To go back to the Invicta and the Forte, did the development go according to plan, or did you have to deal with any particular problems in between?

I’d say we were probably 6-7 months behind schedule with the Invicta. Nobody knew about it because it was our first product, but this brake cylinder looks very simple from the outside, but it’s a good idea, and it represents our way of seeing things and our quality.

The Forte crankset and its Load Cell brake

So, my idea was that these cylinders should hold 1 million activations at 100 bars of pressure. If you think about it, that’s enormous! It’s way above that of a racing car. It’s even higher than that of a road car. What’s more, in a race car, the brake cylinders are rebuilt every season for safety reasons.

So… We made a first prototype and it lasted, I think, 6 or 700,000 activations, which isn’t bad! We were happy, so we kept going and wanted to launch production… No matter what we tried, new problems kept cropping up.

And I’m sure some companies would have launched their product much sooner, but we refused to launch the model until we’d reached the quality standard we wanted. So it didn’t go exactly as planned, it was much harder to develop than I could have imagined. It was hard. Very hard.

And with the Forte, I’d say it was easy as pie. You know, we see things as a “platform”, which is something you’ll see as the years go by. Even if you buy our cheapest model, you’ll be able to improve it over time.

For pedals, you can buy our cheapest crankset, but you’ll always be able to upgrade it to an Invicta. We think of our products as “platforms”, and we knew that when we launched the Invicta. We knew the Forte was coming, so everything had to be identical,

we just had to develop a new brake cylinder. It was quick and easy.

What about the La Prima crankset, any idea when it’ll be released?

We came up with this idea when Asetek entered the SimRacing market, that Invicta would be the top-of-the-range, Forte the mid-range and then the La Prima would be our entry-level.

But it’s still rather high-end compared to some competitors, but for us it will be entry-level. The idea was to launch products for the end of the year, which may or may not happen… We’ve been pushed around like all companies, whether it’s simracing or not. It’s hard to get components from China, whether it’s electronic chips..

But on top of that, we have our own factory and offices in China, and our biggest suppliers are in China, and because of Covid they’ve been shut down overnight. All of a sudden, we can’t receive such and such a thing. For example, brake cylinders were a problem recently, and our manufacturer was suddenly shut down. So everything fell a little behind schedule.

Our Direct Drive base and flywheels should have been released a long time ago, but for the same reasons we’ve fallen behind on them.

Are you feeling the effects of inflation and interest rates on other brands?

Yes. Our core business is liquid cooling, and we’re a listed company so anyone can read our financial reports. Our revenues have fallen by 40%. So yes, we’re massively affected. And for us, the truth about the SimSports market is that it’s not a business yet, it’s an investment.

But you can certainly see the difference in sales compared to the launch of Invicta, and now

it’s two different worlds! So obviously we can see that, but we can also see that the entry-level products and brands that have entered the market are the ones that are selling at the moment.

They’re doing very well, there’s Moza, Simagic, Fanatec for example, who are coming out with entry-level products and I think they’re doing very well at the moment. But we’re not panicking because we’ll never be the cheapest, that’s not our goal.

We want to produce top-of-the-range products at, let’s say, mid-range prices. As a European company, we can’t compete with the prices of Chinese companies, because costs are very different

As we know, we have offices in China! So, as long as we have engineers in Europe

and the United States, we won’t be able to compete on price. That said, I think we can get close, because we’re in mass production.

And we innovate in the way we think about the product. A lot of people have looked at our way of doing things and said “You’re using cheap Load Cell sensors, you need high-capacity Load Cells”. But I have to say… I think it’s stupid!

Stupid to use a $30 sensor when you can get away with using a $5 sensor with the right characteristics. So obviously we’re trying to design around that to be able to sell at affordable prices, because of course we could put a $30 Load Cell sensor in there, but then you have to add the retailer’s margin, you have to add our margin, you have to add VAT, so your $30 sensor for the customer means a $100 increase on the crankset. And I wonder why!

What’s the Asetek touch?

I think it’s our ability to innovate. If you look at our cranksets, I think there are several things we’ve done more intelligently than at least some others… And bearing in mind that this is our very first product in the world of sports simulation, that makes me pretty proud.

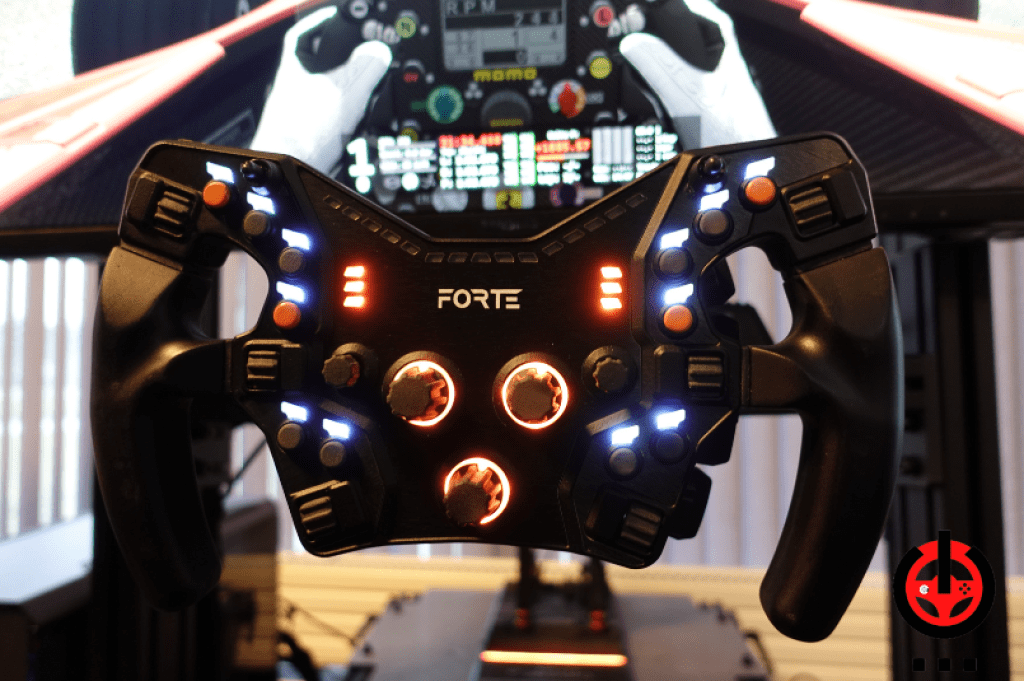

I think when you look at… Our steering wheels, for example! A steering wheel is a steering wheel, it’s difficult, you’re not going to make a triangular steering wheel! So the steering wheel, in my opinion, is a matter of taste… Thin, thick, big, small

10 buttons, 20 buttons, displays or not..

But if you look at our base, I think they bring a few innovations. When we launch our chassis too, I think we’ll see some new things. And even with the brakes, I know there’ll be more surprises to come. So I think our innovations but also our courage to do things differently.

As you probably know, there’s a big debate going on: should a brake be soft?

should it be hard, should it be long or short. And you see… We know what a brake feels like in our race cars, and here we have two different ones.

So of course the brakes aren’t identical, but still, they’re firm, they’re hard and they’re relatively short. And thanks to the adjustment range of our brakes, we can replicate it. We launched this product and got a lot of pushback at first, but now I see competitors copying us, saying “Now we’ve got a two-phase brake!” It makes me laugh!

And then we’ve got thousands of customers now giving us feedback and saying “Wow, the first two days I really didn’t like it but now I love it!”. I think that’s our strength.

Do you think you can still innovate with the Direct Drive bases?

Yes, I think we can. There are different levels of innovation. Logitech has just released its new Direct Drive

i haven’t tested it, but I think it’s very ugly and crude. I don’t know what they had in mind. But that’s a matter of taste!

They can say the same thing about our products, I don’t care. But if you look at our bases, they’re pretty thin

with a pretty nice design. You’ve seen our Quick Release, I think it’s very innovative. You may or may not like LEDs, but we come from the gaming world and I think a lot of people like LEDs, even on pedals, and they’ll be on our chassis too.

And the cool thing is that if you don’t like them you can turn them off, but if you like them and don’t have them, you can’t turn them on.

So I think there are a lot of innovations like that. We also have the front support.

Have you seen it? It’s completely integrated, very clean.

And if we’re talking about the original idea, which is to feel like you’re in a racing car, I think there are a lot of bases on the market that are already doing a great job. And it’s hard to beat that

but I think for example… our partnership with Kévin Magnussen…

Tons of people drive simulators, they launch Assetto Corsa and drive F1 cars

but at the end of the day, nobody knows what it feels like to be in a Formula 1 car. I don’t know what it’s like! I’ve never driven one. But Kevin and I are partners. He spent a lot of time here with our engineers, saying “We need to change this setting, this one, because it must feel different when I hit the vibrator…”.

And in the end, we’re going to be able to come up with a setting that really gives the feel of a real F1 car. And by the way

it may not be the fastest setting for racing, but it’s the feeling. Then you can go and change the setting. “Okay, now I’m going to race, so I’ll set it to the fastest”. But if you really want to “simulate” a real car, you’ve got Magnussen mode.

I mentioned innovation earlier as one of our strengths, but that’s also one of the things I insist on a lot: we want to feel like we’re in a real car. And that’s what we can do with the base. Of course, other people can also partner with an F1 driver.

But you see, simracing has been around for over 20 years, so don’t ask me why nobody did it before us! For me, it’s also innovation.

I think for us, marketing has to translate into real functionality – that’s what brings real value to the user. And that’s what I like about Kevin, because..

I’m not saying we’ll never release a “Magnussen Edition” product with his signature or anything like that. But what he’s really interested in is innovating and doing things that give the same feel as the real car rather than just sticking his name on it. I think that’s a good thing.

The question everyone’s always asking: any idea of the price of the Invicta base?

Yes, of course I do!

I’ll put it this way… We’ve got the Forte base and we’ve got the Invicta base at the moment. The Forte will have 18Nm of torque the Invicta 27Nm. They will share exactly the same features. Same material, same quality, same encoder, same electrical transmission system. If memory serves, the Forte will have slightly fewer LEDs.

But for the rest, they’ll be completely identical, and I think that the Forte base, at least as we speak, will be the least expensive base on the market at this torque level. And the Invicta will be not far above that.

But there’s another way of putting it: it’s like with Invicta pedals. I think people are sometimes surprised to have this level of power and quality at this price level, and we’re not just here to supply an industrial motor! We supply a base with a Quick Release, with a torque cut-off button, a remote on/off button and our basic fixed-mount model. And then people can buy what they want to fix it if what we give doesn’t suit them.

So it’s a complete product! And I think that’s something to keep in mind. When people compare prices between bases, they just look at the engine. They don’t take into account that after that you have to buy a $100 bracket, sometimes a $100 torque cutter, and sometimes even a Quick Release.

All of a sudden, you’ve spent an extra $300 on your base, which seemed reasonably priced at the outset, but by the time you get to the cash register is much more expensive!

In the future, we’d like users to be able to buy a complete chassis from us with everything inside. Except for the computer, because we don’t know who has a computer, who wants a console or a PC – our customers are PC manufacturers. Believe me, Asetek has no money to make trying to compete with Alienware, for example.

They do a much better job of that. But the point is that as a user you can put this in your basket, a complete simulator and everything is included. And then you can assemble it yourself, or you can have one of our dealers assemble it for you. We’re not going to assemble them ourselves.

We’ll be releasing our chassis next year, and after that I’m hoping for seats too. So if we take stock we’ll have seats, chassis, bases, pedals, steering wheels, and we’re almost there.

In the live Q/R you mentioned a vintage gearbox, can you tell us more about that?

I don’t want to give away all our ideas to our competitors, but if we launched it tomorrow I could talk about it. But yes, we know that people love vintage vehicles and racing, and we also understand that simracing is a very hardware-based sport. I love hardware myself, I love everything to do with technology. And of course, using a GT or Vintage steering wheel isn’t going to make you any faster

but we’re talking about authenticity. In simracing, it’s fun if you want to drive an old Ferrari

to have a wooden steering wheel and the gearbox and pedals and so on. So we’ll do that too eventually.

Do you plan to release other products with Pagani or other brands?

Yes. I’d say that at the moment, given the state of the market, we’re in a depressed year. I think the very expensive high-end products are hurting us.

You can see it in our sales, what’s selling and what’s not. Having said that, I think what we did with Pagani was great.

And yes, we want to launch more products with them and we’d like to do it with other brands too. I think… And this has nothing to do with Simracing, but I think in the future, when you go to a dealership…

Let’s say you go to BMW, in Denmark we have the highest car taxes in the world. If you want a $100,000 car, it’ll cost $300,000 by the time you’ve paid all the taxes. And it also means that dealers don’t carry large stocks.

So if you go to a dealership and want to try out an M2, they could bring out the simulator, program it to reproduce the feel of an M2. And then you want to try out an M5 or an M6 or whatever, and you can do all that in a simulation. So I think simulators are going to play an increasingly important role in the automotive industry in general.

How can you get out of your comfort zone in a sector you already dominate as an entrepreneur?

I think one of the basics is just to be confident. You know, a lot of people write to me, “You don’t know what you’re talking about, you don’t know the racing world…” Things like that. But I’m confident because, yes, I know racing. I’m also an engineer, I’m also a designer, that’s my job, I know how to make things myself. And when we had our F4 team, I was the engineer, I monitored the data, made the adjustments so… I understand racing pretty well and I wasn’t afraid to enter this market.

A lot of the product ideas come directly from me as an entrepreneur. And most of the time these ideas come because I see things I’d like to change compared to our competitors. There aren’t too many competitors in the simulator world that we haven’t analyzed

or that I haven’t tried, or that I haven’t come across on a track or elsewhere. And most of the time, the ideas come from the fact that they’re doing things in a way that makes little financial sense.

We can do it cheaper or smarter, or better. For example, when you see our chassis

There are a lot of possible adjustments that would normally cost a lot of money to make, and as an entrepreneur as a person, you have to be prepared to take risks if you’re not prepared to take risks, forget it.

Here’s an example: the company only operated in Denmark in 2005-2006. And I was emailing the big PC manufacturers all the time, but nothing ever came of it. It was impossible to stay in Denmark and work with Dell in Texas. So I figured we had to be in the USA.

So I moved to the States and opened our offices there to be closer to our customers

but we had no money! My wife and I left together with our two children and there was enough money in the Asetek coffers to last a few months. So my job was to get closer to customers, open the American offices and raise funds.

And if I couldn’t raise the money, there wouldn’t even be enough to buy the plane tickets to get home. And I don’t think a lot of people would have had the guts to do that. But we told ourselves it was an adventure. It’s just money, and if it goes wrong, yes, we’ll have lost money, but so what? We’ll start again! Now, the years have gone by and we can see that it worked, so I’d say just go for it!

Asetek = André Sloth Eriksen Technologies?

Yes! In fact, in Denmark over 20 years ago, it wasn’t popular to be an entrepreneur; people thought you were crazy if you wanted to start your own business. So I had a job with Danfoss, which is one of the biggest, well probably the biggest industrial company in Denmark

in their management trainee program so I had a management career in a global company that I could have climbed into.

And I thought I wanted that! And then I founded Asetek because I had this idea for a compressor cooling system. It was the Vapochill project. But to be able to buy the parts I needed, I had to set up a company. Because as an individual I couldn’t buy refrigerator compressors. So I had to set up a business, so I started a small private company just to be able to buy the compressors and do my hobby. I didn’t see it as a business or a future career at all, but it took off, sales soared and after a while it didn’t make sense to change the name of the company. But it’s still André Sloth Eriksen Technologies. I didn’t think much of it, it wasn’t very clever, but there it is.

Thank you André Eriksen, and thank you to the team!

Many thanks to André Eriksen for the precious time he devoted to us. But also to the whole Asetek team, who gave us an exciting day at their HQ.

What to see We visit the Asetek factory and test Kévin Magnussen’s chassis